09/09/2024

Innovation and efficiency are the cornerstones upon which Guerrini Lauro has built its reputation in the field of automatic turning. Thanks to the multispindle lathes in our machine park, we have the opportunity to further elevate our production standards. We can now respond even more effectively to the diverse needs of our clients. In this article, we will discuss what a multispindle lathe is, how it works, the advantages it offers, and the types of machining it allows.

A multispindle lathe is a machine tool equipped with multiple spindles that allow the simultaneous machining of different parts of a workpiece. This enables:

Using a multispindle lathe in precision mechanics offers numerous advantages. The main ones are:

Traditional machining with single-spindle lathes often requires multiple steps and various setups to complete a complex component. This not only increases production times but can also introduce variability in dimensional tolerances and the quality of mechanical components produced.

In contrast, machining with a multispindle lathe allows for complex operations to be performed in a single step, ensuring greater uniformity and precision during machining. This technology is particularly advantageous in some of the sectors where Guerrini Lauro operates, such as automotive, electrotechnics, and pneumatics, where technical specifications are stringent and production volumes are high.

Our product range includes high-precision turned components for various industrial sectors. The multispindle lathes allow us to further enhance the quality of our products, reduce delivery times, and increase our production capacity.

Multispindle lathes are a fundamental tool for offering clients more advanced and competitive solutions. Our dedication to innovation and quality allows us to maintain a leading position in the sector of automatic turning.

Multispindle Lathe: Maximum Productivity in Turning

Innovation and efficiency are the cornerstones upon which Guerrini Lauro has built its reputation in the field of automatic turning. Thanks to the multispindle lathes in our machine park, we have the opportunity to further elevate our production standards. We can now respond even more effectively to the diverse needs of our clients. In this article, we will discuss what a multispindle lathe is, how it works, the advantages it offers, and the types of machining it allows.

- Multispindle Lathe: What It Is and How It Works

- Advantages of the Multispindle Lathe

- Comparison Between Machining Types: Traditional vs. Multispindle Lathe

- Our Application Sectors

- Guerrini Lauro Products

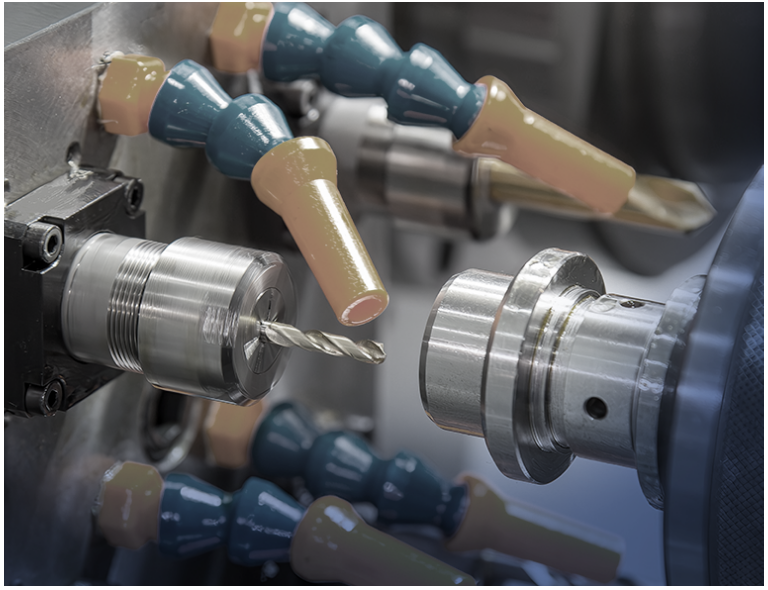

Multispindle Lathe: What It Is and How It Works

A multispindle lathe is a machine tool equipped with multiple spindles that allow the simultaneous machining of different parts of a workpiece. This enables:

- Significant reduction in production times

- Increased productivity

- Higher precision

Advantages of the Multispindle Lathe

Using a multispindle lathe in precision mechanics offers numerous advantages. The main ones are:

- Increased Productivity: Simultaneous machining on multiple spindles reduces cycle times, allowing for faster production.

- Precision and Quality: The ability to machine multiple sections of the workpiece synchronously ensures tighter tolerances and better surface finish.

- Flexibility: Ideal for the production of complex components, thanks to the capability to perform multiple operations in a single setup.

- Cost Reduction: Less downtime and greater efficiency result in lower operational costs.

Comparison Between Machining Types: Traditional vs. Multispindle Lathe

Traditional machining with single-spindle lathes often requires multiple steps and various setups to complete a complex component. This not only increases production times but can also introduce variability in dimensional tolerances and the quality of mechanical components produced.

In contrast, machining with a multispindle lathe allows for complex operations to be performed in a single step, ensuring greater uniformity and precision during machining. This technology is particularly advantageous in some of the sectors where Guerrini Lauro operates, such as automotive, electrotechnics, and pneumatics, where technical specifications are stringent and production volumes are high.

Our Application Sectors

- Fittings: In the fittings sector, precision is crucial for ensuring the reliability of connections. Our multispindle lathe allows us to produce high-quality fittings with tight tolerances, ensuring optimal and long-lasting performance.

- Automotive: In the automotive sector, precision and speed are critical. Components must be produced with extremely tight tolerances to ensure safety and performance. The multispindle lathe enables us to produce complex parts like camshafts, gears, and fittings with impeccable quality and reduced lead times.

- Valves and Hydraulics: The production of components for valves and hydraulic systems requires precise and reliable machining. With our multispindle lathe, we can manufacture high-precision valves and hydraulic components, ensuring maximum efficiency and resistance.

- Mechanical: In the mechanical sector, flexibility and precision are fundamental for producing complex, high-quality components. Our multispindle lathe allows us to machine various types of materials with precision, meeting the specific needs of this sector.

- Plant Engineering and Energy: For plant engineering and the energy sector, producing components with high precision and durability is essential. Our multispindle lathe ensures the production of complex, high-quality parts essential for the efficiency and safety of plants.

- Food and Taps Manufacturing: In the food and faucet sectors, quality and precision are essential for ensuring safety and functionality. With our multispindle lathe, we can produce high-quality components that meet hygiene and safety regulations.

Guerrini Lauro Products

Our product range includes high-precision turned components for various industrial sectors. The multispindle lathes allow us to further enhance the quality of our products, reduce delivery times, and increase our production capacity.

Multispindle lathes are a fundamental tool for offering clients more advanced and competitive solutions. Our dedication to innovation and quality allows us to maintain a leading position in the sector of automatic turning.