05/03/2025

When we talk about precision machining, turning is one of the most widespread and appreciate techniques. This process allow to realize metal components with high accuracy, meeting the need of sector such as automotive, aerospace, fittings and electronics.

But what make turning so essential, and which technologies have improved its effectiveness?

In recent year, turning has undergone a significative evolution due to the introduction of increasingly advanced machine tools.

The precision mechanical turning is a fundamental pillar of modern industry. With the evolution of technologies, companies can count on increasingly accurate and fast processing, guaranteeing high quality products. Invest in the most advanced solution is the to maintaining a competitive advantage and meeting the needs of an ever-changing market.

An example of excellent in precision machining is represented by Guerrini Lauro, which offers solution of the highest quality

Find out how our machining can meet your specific need.

Lathes and precision machining

When we talk about precision machining, turning is one of the most widespread and appreciate techniques. This process allow to realize metal components with high accuracy, meeting the need of sector such as automotive, aerospace, fittings and electronics.

But what make turning so essential, and which technologies have improved its effectiveness?

- Precision turning: what it is and why it matters

- Advanced technology for turning

- Why choose precision turning?

Precision turning: what it is and why it matters

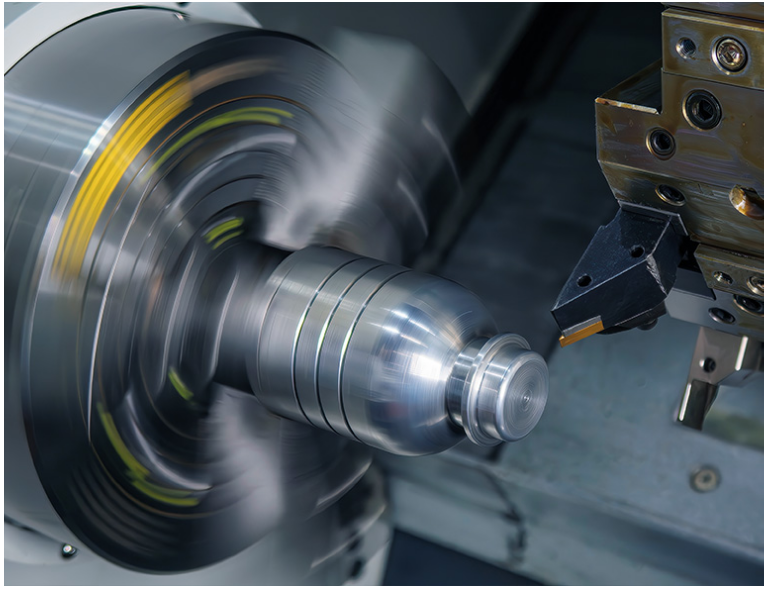

Turning is a machining process that include the removal of chip from a piece in rotation, allowing to get cylindrical, conical or complex shapes with extreme precision. Thanks to technological innovation, today it is possible to achieve very low tolerances, improving the quality of the final product and reducing processing time.Turning types

To better understand the importance of turning, it is helpful to distinguish between the main types of machining:- External turning: consist in the removal of material from the outer surface of the work piece, ideal for the production of shaft, pins and cylinders.

- Internal turning: use to work the inner part of a piece, useful in the production of bushings and hollow components

- Facing, which is used to obtain flat surfaces perpendicular to the axis of the workpiece.

- Groove, to create throat and grooves on cylindrical components.

- Truncation, to separate the piece from the raw material bar.

- Thread, for the production of screws and component with precise thread.

Advanced technology for turning

In recent year, turning has undergone a significative evolution due to the introduction of increasingly advanced machine tools.Numerical controlled lathes (CNC)

CNC lathes have revolutioned precision turning, ensuring repeatable machining with tolerance up to 5 µm. These machine, thanks to digital programming, allow you to perform complex operation with high speed and precision, minimizing the human error.Multispindel lathes

Multi-spindle lathes are a strategic solution for companies requiring high productivity. These machines allow you to machine multiple part at the same time, optimizing production time without compromising quality.Why choose precision turning?

Choosing precision turning, offer many benefits, including:- Superior quality: precision machining reduce the scraps and improve component reliability

- Operational flexibility: Modern lathes allow multiple operation to be performed in one step, increasing efficiency

- Cost reduction: thanks to increased automation, production times are optimized and the operating costs are reduced.

The precision mechanical turning is a fundamental pillar of modern industry. With the evolution of technologies, companies can count on increasingly accurate and fast processing, guaranteeing high quality products. Invest in the most advanced solution is the to maintaining a competitive advantage and meeting the needs of an ever-changing market.

An example of excellent in precision machining is represented by Guerrini Lauro, which offers solution of the highest quality

Find out how our machining can meet your specific need.

Design by

Design by