14/05/2025

In the precision mechanical processing sector, quality is a fundamental requirement. Each component produced must meet rigorous standards to guarantee reliability, durability and safety. Choosing a certified company means receiving components that comply with regulations, made with carefully controlled and tested processes.

In this article, we will see together the importance of quality certification for automatic turning shops. Furthermore, we will evaluate the advantages it offers and why it represents a distinctive element in the precision mechanics sector.

Furthermore, certified companies adopt a structured quality management system, with continuous checks and inspections on materials, processes and final products. The main advantages of a quality certification include:

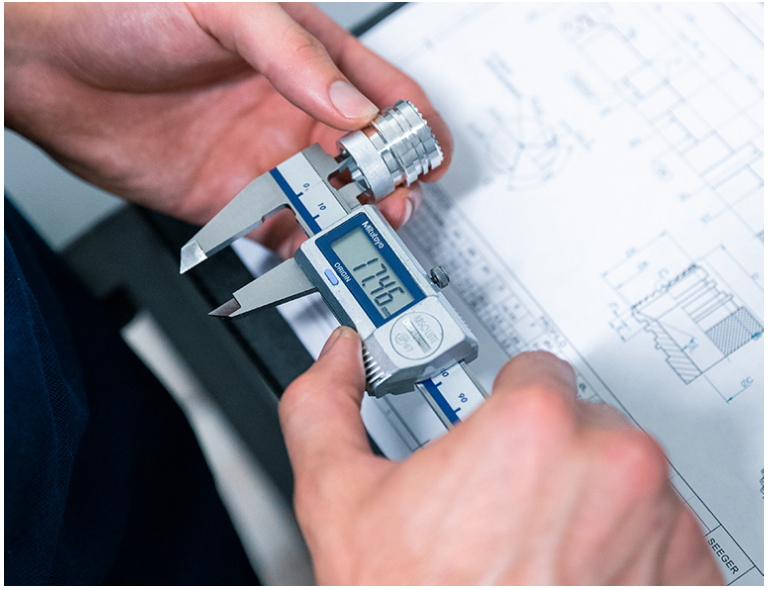

To ensure maximum precision, we adopt a rigorous production cycle monitoring system. Each component produced goes through a careful verification process in our metrological laboratory, equipped with cutting-edge instruments for measuring dimensions, tolerances and finishes.

Furthermore, we collaborate with accredited external laboratories to conduct advanced analyses and in-depth tests, so as to guarantee the conformity of our products even in the most demanding application contexts.

Our company policy allows us to offer customers components turned with absolute precision, accompanied by complete technical documentation. Each supply is synonymous with transparency, reliability and optimal performance. For us, quality is a path of continuous improvement, which translates into innovation, constant training of staff and optimization of production processes.

This is accompanied by risk control and monitoring, analysis of opportunities and internal checks, always oriented towards identifying concrete improvement actions.

In an increasingly competitive market, certified quality is a necessity for those who want to stand out and guarantee maximum value to their customers. Choosing a certified supplier represents a certainty in terms of performance, reliability and continuous innovation.

Quality certification for mechanical processing: why choose it

In the precision mechanical processing sector, quality is a fundamental requirement. Each component produced must meet rigorous standards to guarantee reliability, durability and safety. Choosing a certified company means receiving components that comply with regulations, made with carefully controlled and tested processes.

In this article, we will see together the importance of quality certification for automatic turning shops. Furthermore, we will evaluate the advantages it offers and why it represents a distinctive element in the precision mechanics sector.

- What is a quality certification and why is it important

- Guerrini Lauro's commitment to certified quality

- Why rely on a certified turning shop?

What is a quality certification and why is it important

Quality certifications, such as UNI EN ISO 9001:2015, attest that a company follows rigorous protocols to offer a product that is precise and efficient and compliant with the requirements requested by the customer.Furthermore, certified companies adopt a structured quality management system, with continuous checks and inspections on materials, processes and final products. The main advantages of a quality certification include:

- Greater reliability: production processes are standardized and subjected to constant checks, reducing the risk of errors.

- Reduction of waste: accurate monitoring allows to minimize material waste and production costs, with a positive impact on sustainability.

- Customer satisfaction: certification guarantees that each piece complies with the required specifications, increasing customer trust and loyalty.

- Competitiveness on the market: a certified company has an advantage over competitors, as it offers an objective guarantee on the quality of its products.

- Better risk management: the protocols required by the certifications reduce the risk of defects and disputes, improving the reliability of supplies.

- Traceability of materials: each component is identifiable throughout the production process. This allows to trace the origin of the materials precisely in case of anomalies or complaints.

Guerrini Lauro's commitment to certified quality

At Guerrini Lauro, quality is the beating heart of every phase of the production process. Our decades of experience and constant technological updating allow us to offer precision workmanship that meets the highest quality standards. Our UNI EN ISO 9001:2015 certification demonstrates our commitment to quality management, ensuring efficient and controlled processes in every detail.To ensure maximum precision, we adopt a rigorous production cycle monitoring system. Each component produced goes through a careful verification process in our metrological laboratory, equipped with cutting-edge instruments for measuring dimensions, tolerances and finishes.

Furthermore, we collaborate with accredited external laboratories to conduct advanced analyses and in-depth tests, so as to guarantee the conformity of our products even in the most demanding application contexts.

Our company policy allows us to offer customers components turned with absolute precision, accompanied by complete technical documentation. Each supply is synonymous with transparency, reliability and optimal performance. For us, quality is a path of continuous improvement, which translates into innovation, constant training of staff and optimization of production processes.

This is accompanied by risk control and monitoring, analysis of opportunities and internal checks, always oriented towards identifying concrete improvement actions.

Why rely on a certified turning shop?

Relying on a certified turning shop like Guerrini Lauro means choosing a partner that puts quality first. For those who operate in sectors where quality is essential, collaborating with companies that adopt certified standards allows you to: reduce risks, increase productivity and obtain products that comply with the highest expectations.In an increasingly competitive market, certified quality is a necessity for those who want to stand out and guarantee maximum value to their customers. Choosing a certified supplier represents a certainty in terms of performance, reliability and continuous innovation.

Design by

Design by